Vibration dampers offer a significant advance in the protection of cranes during sheet pile driving and pulling operations. A comprehensive comparison was recently carried out using a vibration damper during sheet pile pulling.

The comparison structure

For this comparison, a Tadano ATF 100G-4 crane and the Müller MS-A 420 V vibro-hammer with a free rider MS 20 HFV were used. The sheet piles pulled were double planks PU 18, each 8.50 meters long. To ensure precise measurements of the vibrations, the profound VIBRA+ technology was used, which provided detailed insights into the vibrations transmitted to the crane.

Measuring points

Vibration measuring devices were strategically placed at two critical points on the crane:

- Crane ballast: To monitor the vibrations that affect the stability of the crane.

- Outrigger: To detect the direct effects of the vibrations on the structure of the crane.

(zum Vergrössern mit bitte auf Bild klicken)

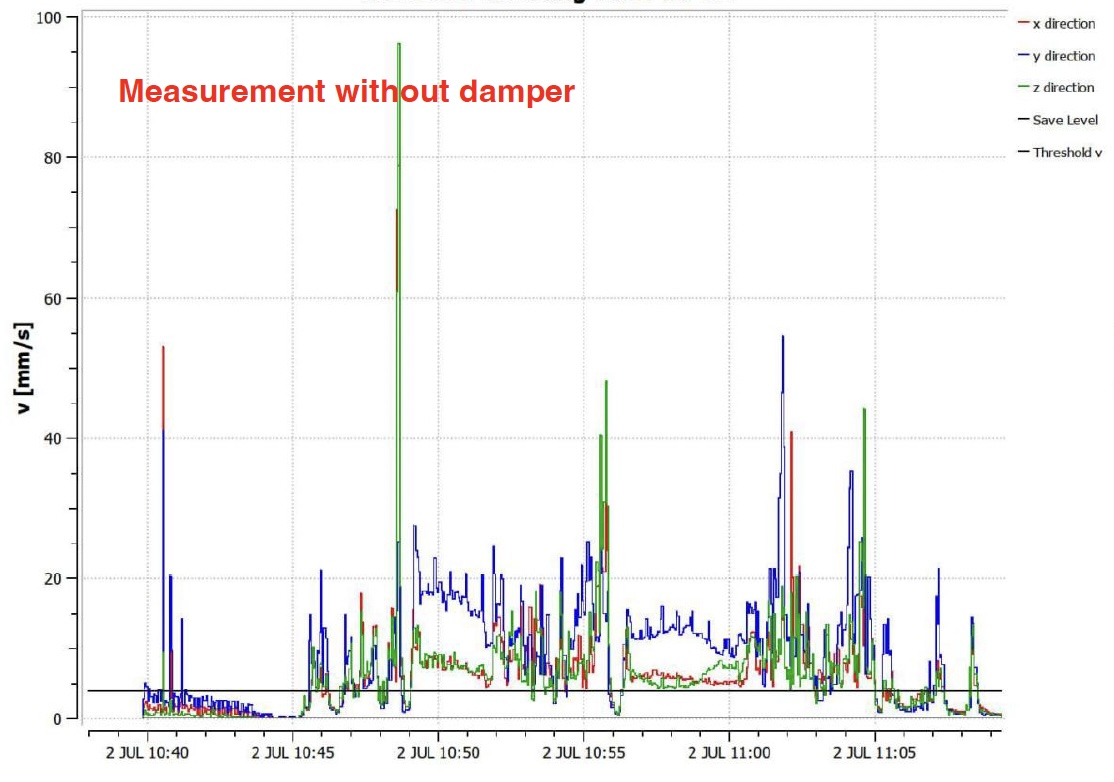

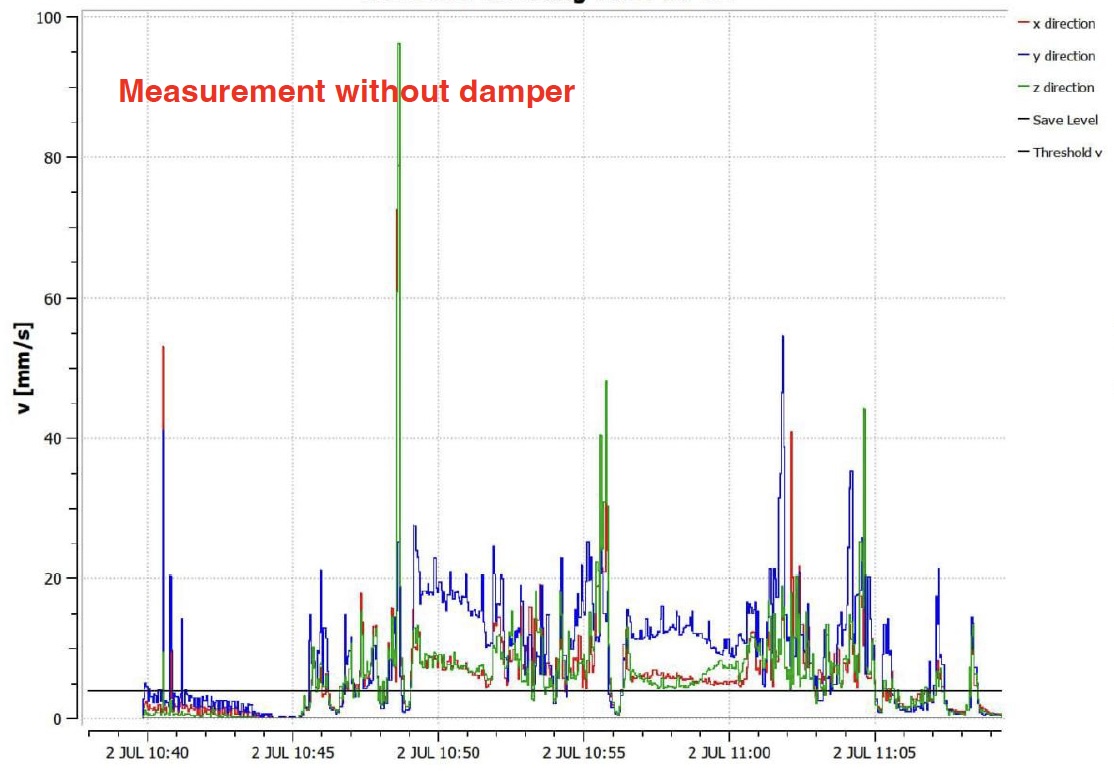

crane protection with vibration dampers for vibro hammers result without dampers

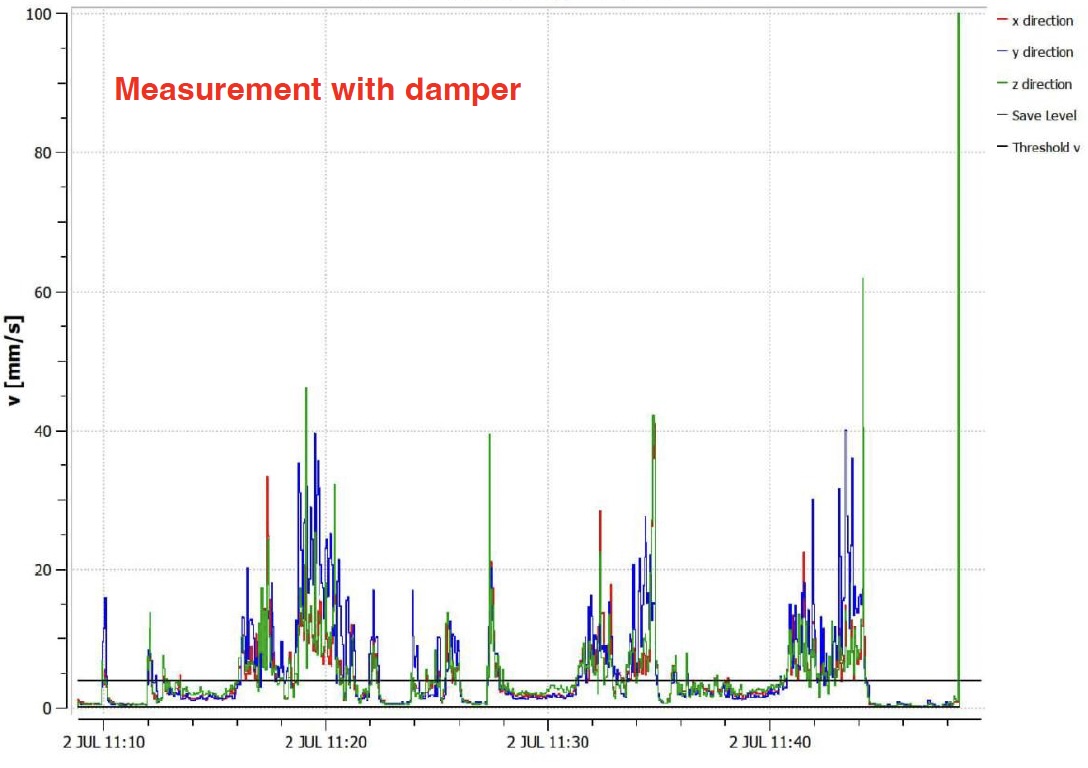

crane protection with vibration dampers for vibro hammers result with dampers

With the help of the vibration damper, harmful vibrations were reduced by an average of 50% in this comparison. Effective crane protection and positive feedback from the crane operator are the pleasing results.

Comparative Measurements

The test involved comparing vibration levels during the extraction of sheet piles, both with and without the vibration damper.

- Without Damper:

- On Ballast: Significant vibrations were recorded, highlighting the intense impact on the crane’s stability.

- On Support: High vibration levels were observed, indicating potential long-term damage to the crane’s structural integrity.

- With Damper:

- On Ballast: There was a substantial reduction in vibrations, showcasing the damper’s effectiveness in protecting the crane’s stability.

- On Support: Vibrations were significantly minimized, demonstrating the damper’s capability to safeguard the crane’s structural components.

Results

The comparative analysis clearly showed that the vibration damper drastically reduces the vibrations transmitted to both the crane’s ballast and support when the sheet pile is extracted. Here are the key takeaways:

- Enhanced Crane Stability: By reducing the impact of vibrations on the ballast, the damper ensures safer crane operations during pile driving and extraction, preventing costly maintenance and downtime.

- Protection of Structural Integrity: The reduced vibrations on the crane’s support have a positive impact on its structural components, supporting the crane’s operational lifespan and enhancing safety for operators.

- Operational Efficiency: With minimized vibrations, the crane operates more smoothly, leading to increased efficiency and reduced wear and tear.

Vibration dampers underscore their potential to optimize pile driving and sheet pile extraction operations. By significantly reducing vibrations, these innovative damping solutions protect cranes, enhance safety, and boost operational efficiency.

Vibration dampers are available for different crane types and pull-force requirements for implementation in your operations, promising unparalleled protection and performance for sheet pile extraction.